When people think about the brick manufacturing industry they rarely associate it with environmentally friendly practices. The good news is that there are now many eco brick making machines hitting the marketplace. These machines are designed to provide brick manufacturers with a faster, automated way to make bricks while minimizing the impact on the environment. There are plenty of reasons to believe that ecological block making machines will become more popular in 2020 – after all, countries around the world are becoming more conscious of the potential damage human activity is doing to the planet. Here are 4 key benefits of eco brick making machines:

• Less Noise Pollution

Thanks to the latest hydraulic transmission technology, eco block machines produce less noise during operation than older models. In addition, the newest machines have electric motors as opposed to diesel motors, which means noise from the motor is significantly reduced.

• Zero Emissions

Eco brick making machines run off electricity rather than fossil fuels like diesel. This means that they do not produce any carbon emissions or hazardous pollutants in the atmosphere. Furthermore, the latest machines are fitted with advancing dedusting filtering systems to prevent dust pollution when mixing cement for concrete blocks.

• Recycle Construction Waste

To be fair, almost any type of block making machine can be used to convert construction waste, like slag and fly ash, into profitable bricks for the building industry. When construction waste is converted into bricks rather than sent to landfill sites or incinerators, there is less environmental damage caused.

• Reduced Labor Costs

Full automatic eco block making machines can automate just about every stage in a brick making production line, reducing the manual workforce requirements. As labor costs are often the highest expense brick manufacturing businesses have to absorb, automatic brick machines can lead to huge increases in annual profits for businesses in the field.

Eco Brick Making Machine Manufacturers

There are quite a few manufacturers producing eco brick making machine for the marketplace. In 2020, there are likely to be a lot more manufacturers getting involved, which could translate to more competitive prices. At the moment, the best way to get good price deals on modern block making machines is to contact suppliers in China and India. Most domestic suppliers don’t even come close to matching block machines prices in many Asia countries. Fortunately, most manufacturers based in Asia ship their products to global destinations.

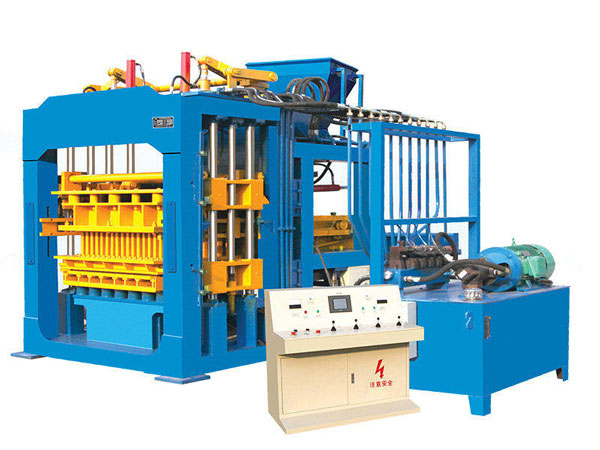

Eco Brick Making Machine Specs

Some of the machines specs to pay attention to when looking for the most suitable model for your operation include rating pressure, vibration type, vibration frequency, cycle time, pallet size, power, dimensions, automation grade, capacity (bricks/hour), tolerance, minimum order quantity, weight, and brick type. Many eco block machines are multifunctional devices and can be used to make a wide range of different brick types, such as hollow blocks, interlocking blocks, curbstones, pavers, concrete bricks, etc. As you can see, there are a lot of things to take into account when searching for the best machine for your environmentally friendly brick making business:https://aimixgroup.ph/eco-brick-making-machine/.